Air Intake Control PCB

Problem Statement

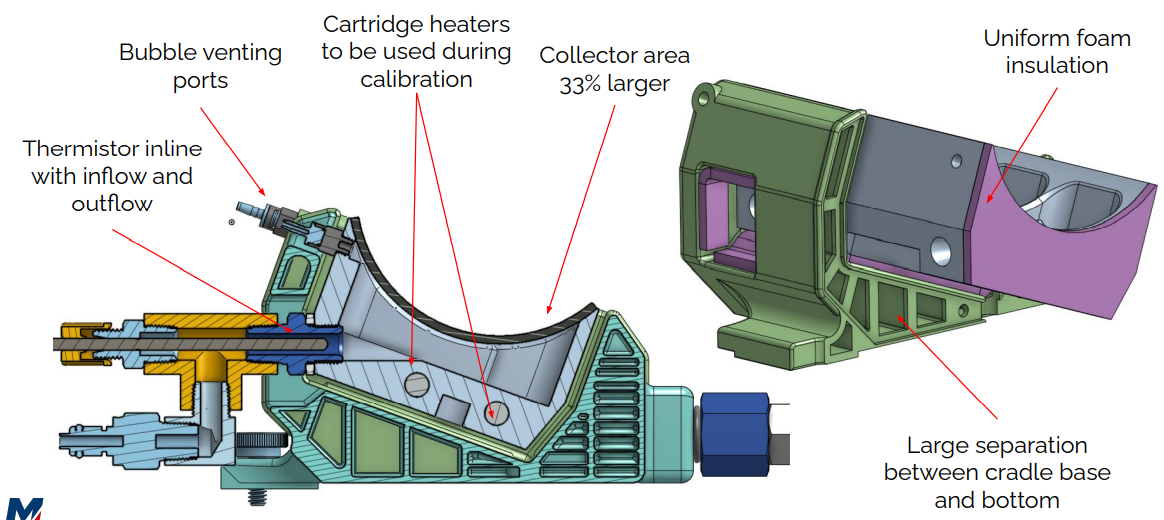

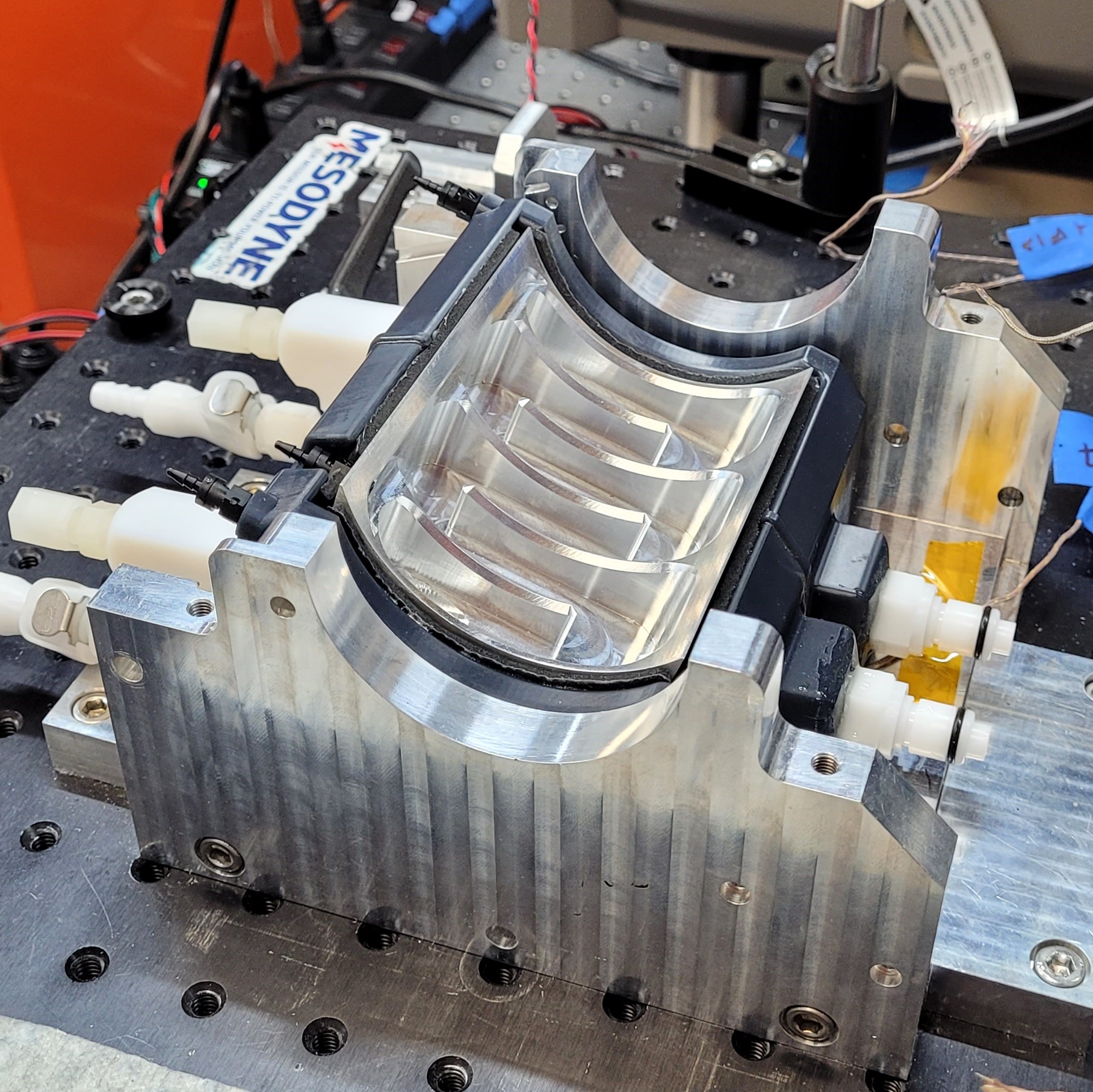

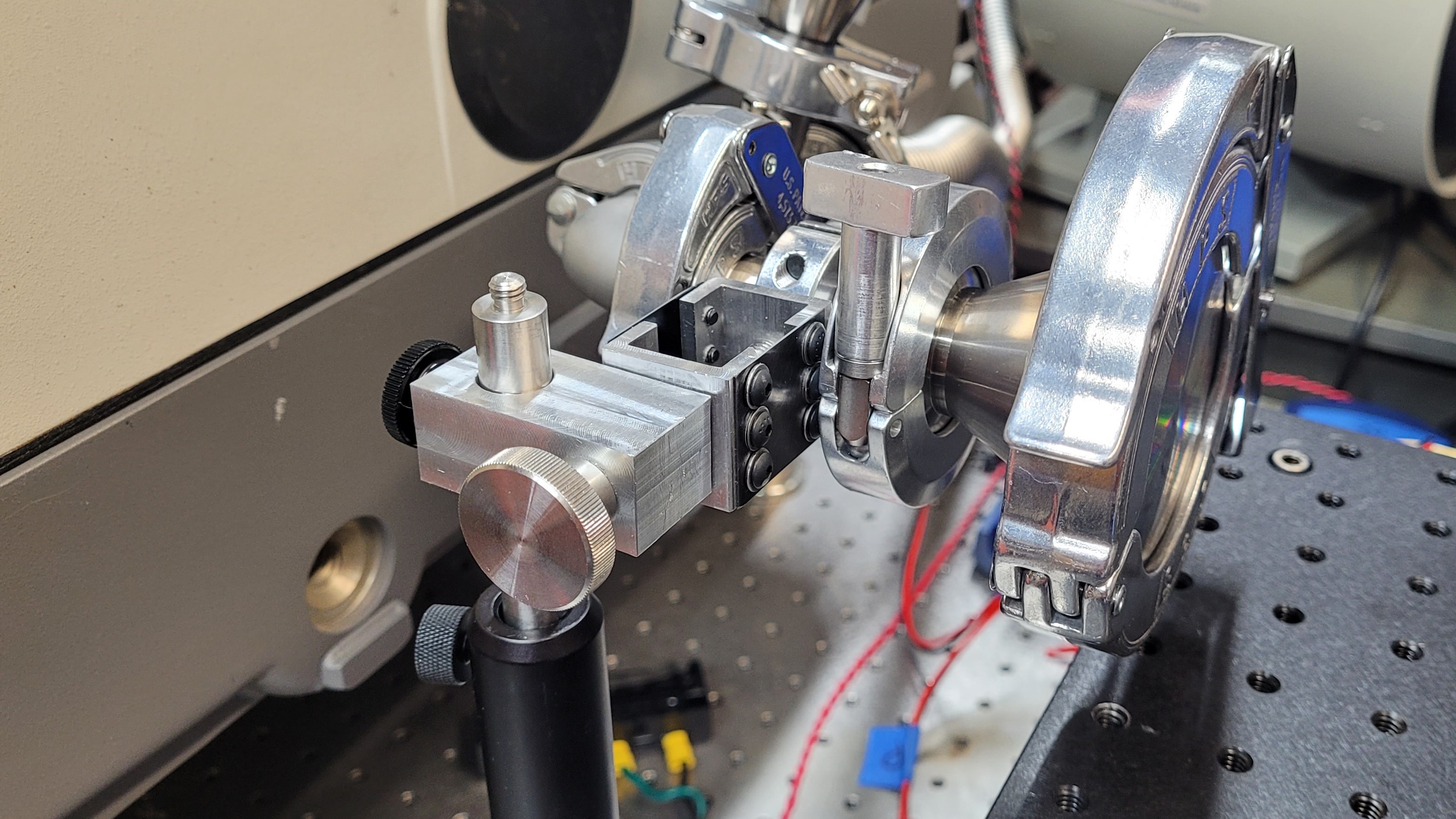

To develop a miniature blower module that sustains propane combustion within a LightCell power generation unit.

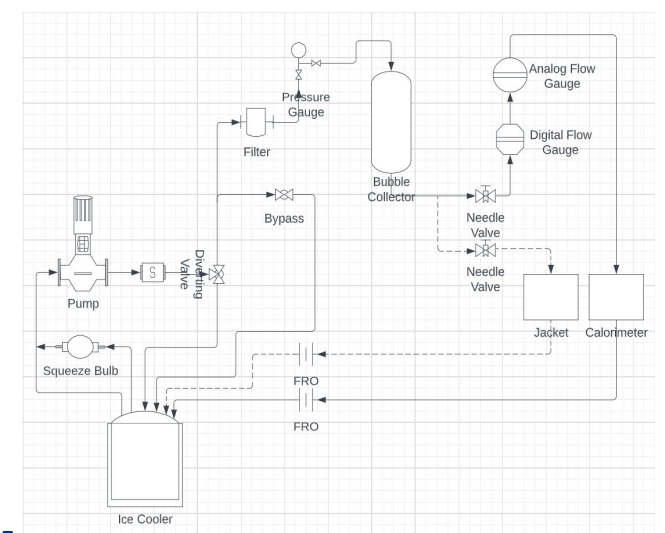

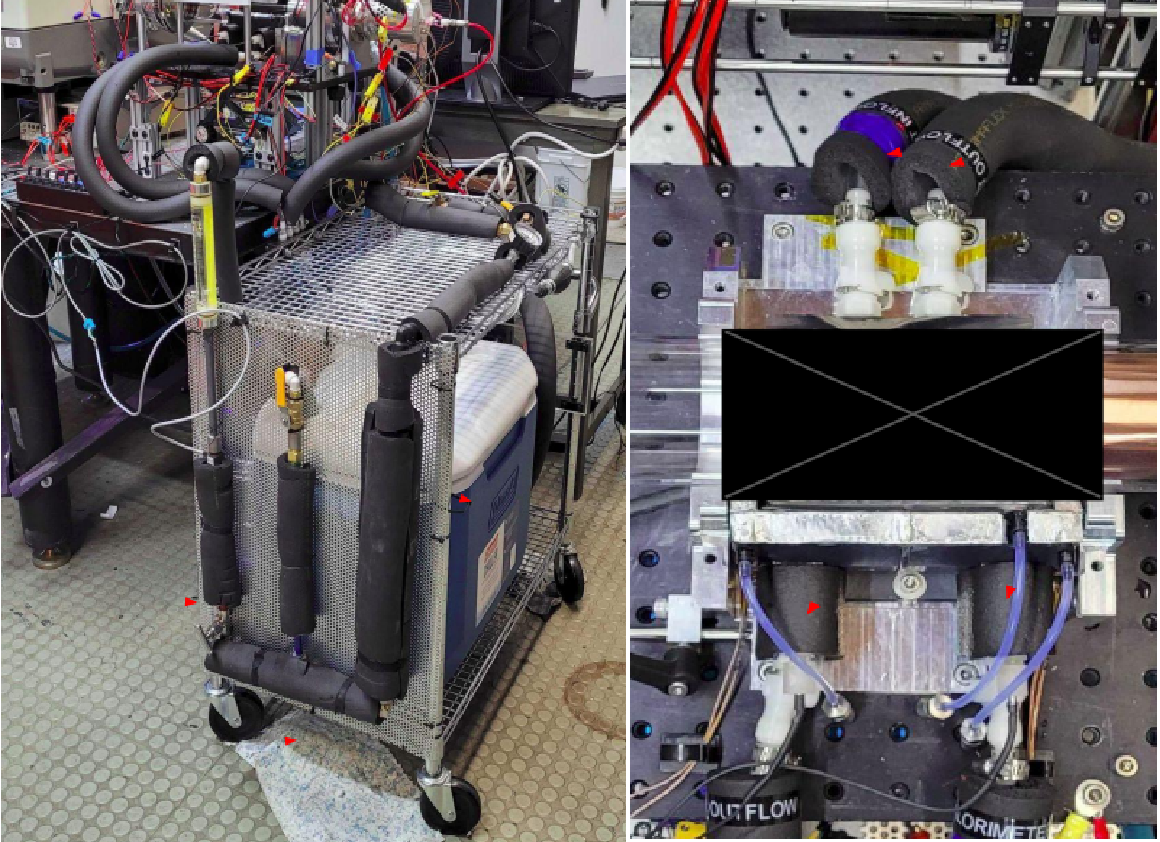

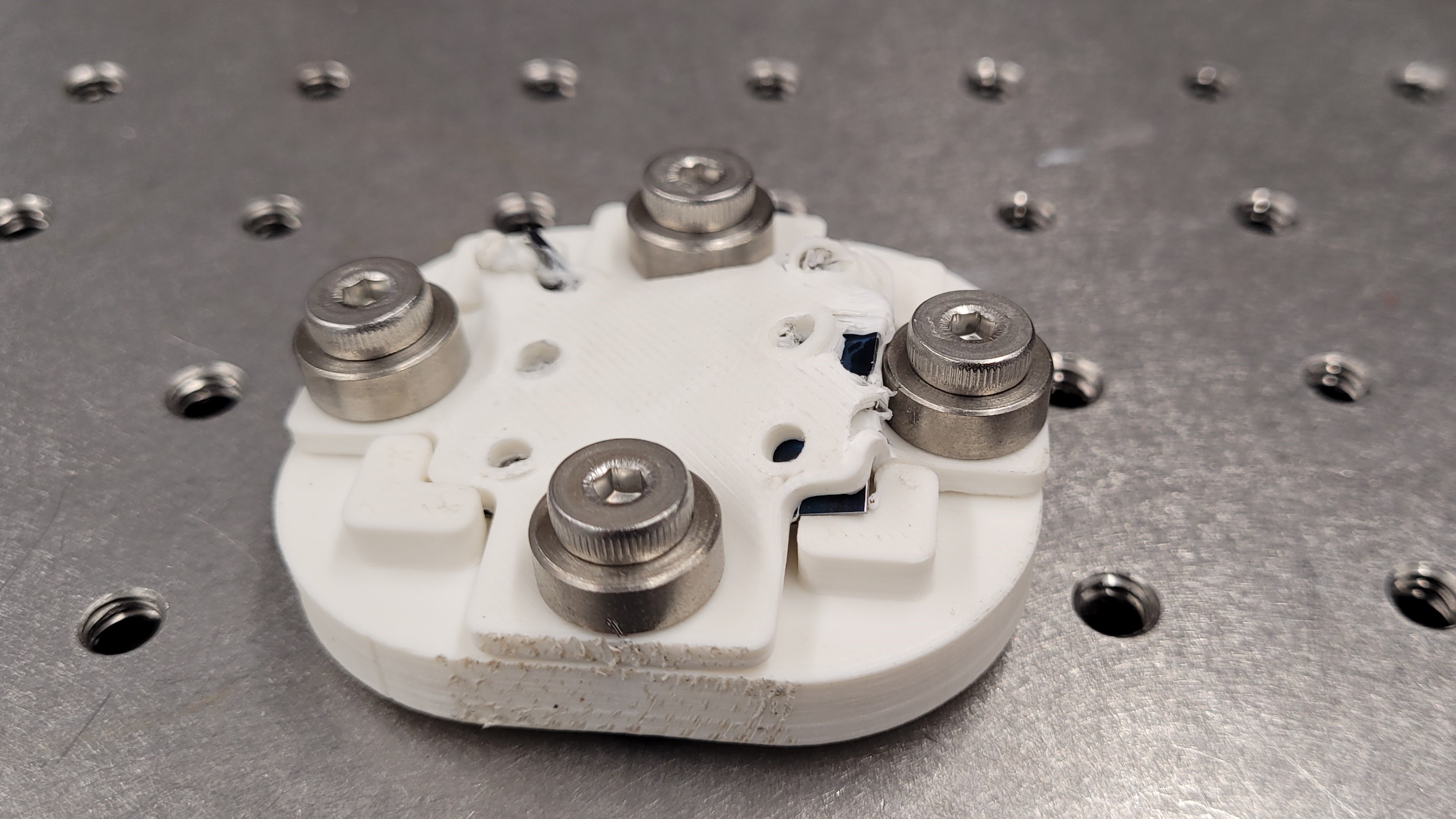

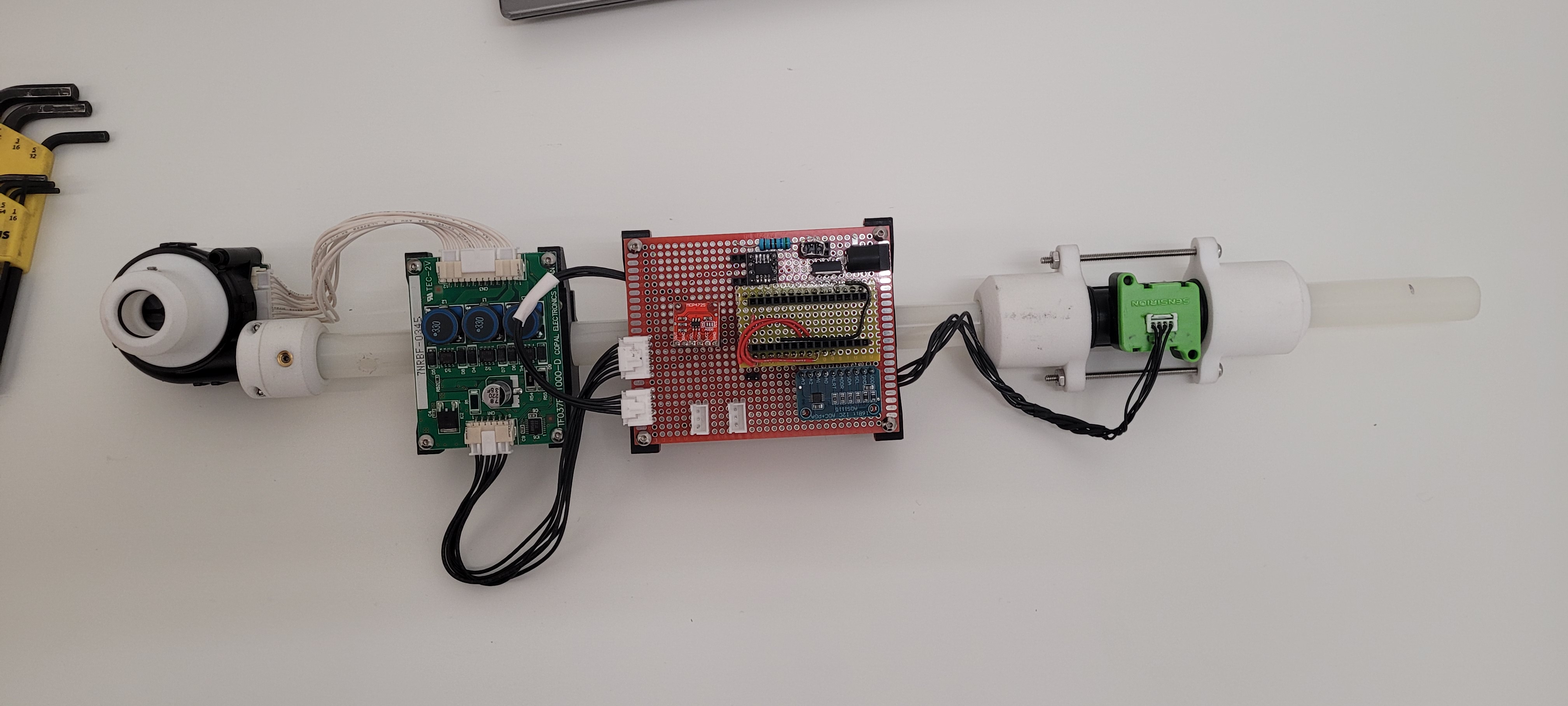

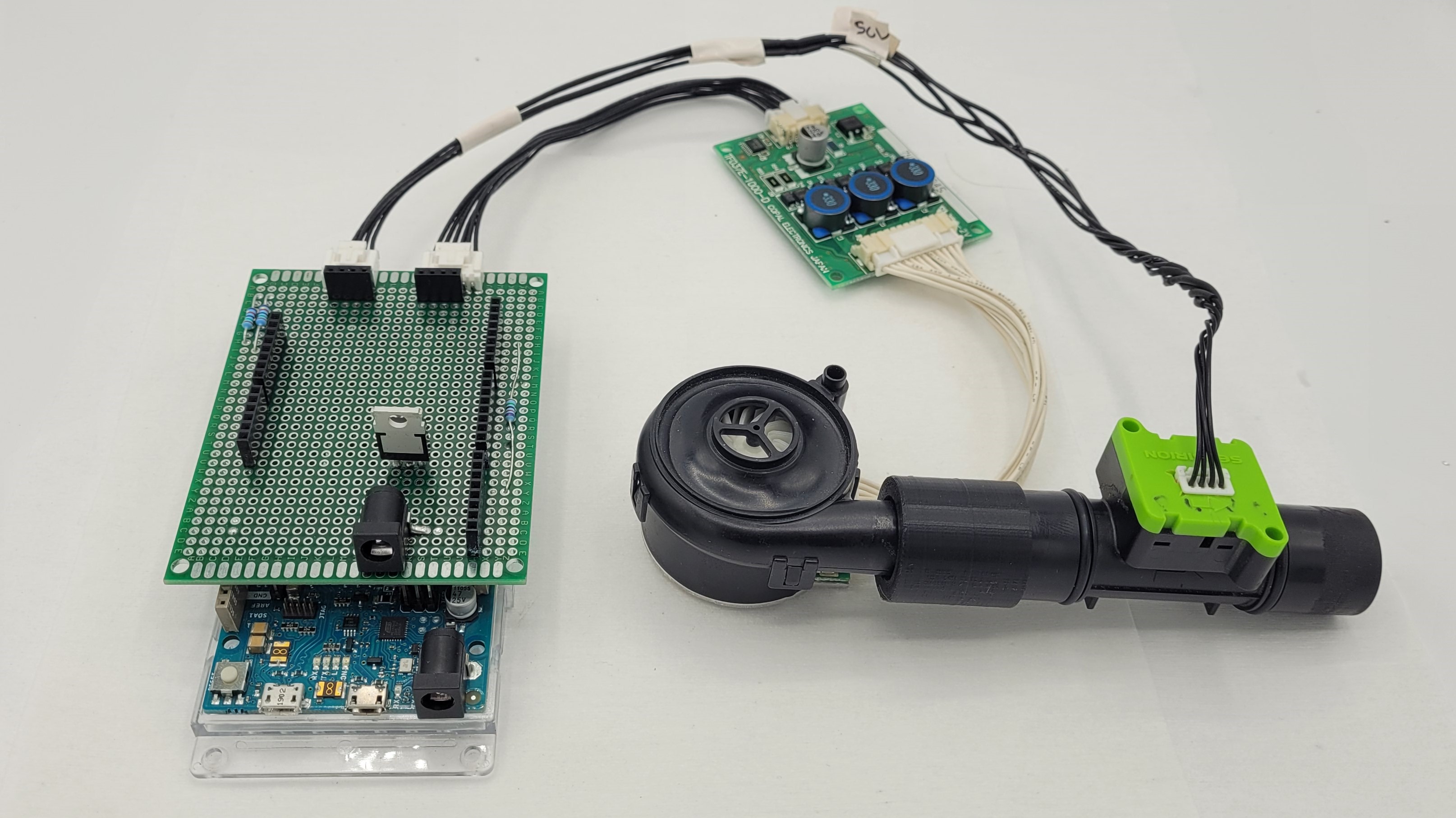

Iterations and Prototyping

Three different controllers were used in the prototyping stage: Arduino Due, Adafruit nRF52, and the Arduino Nano.

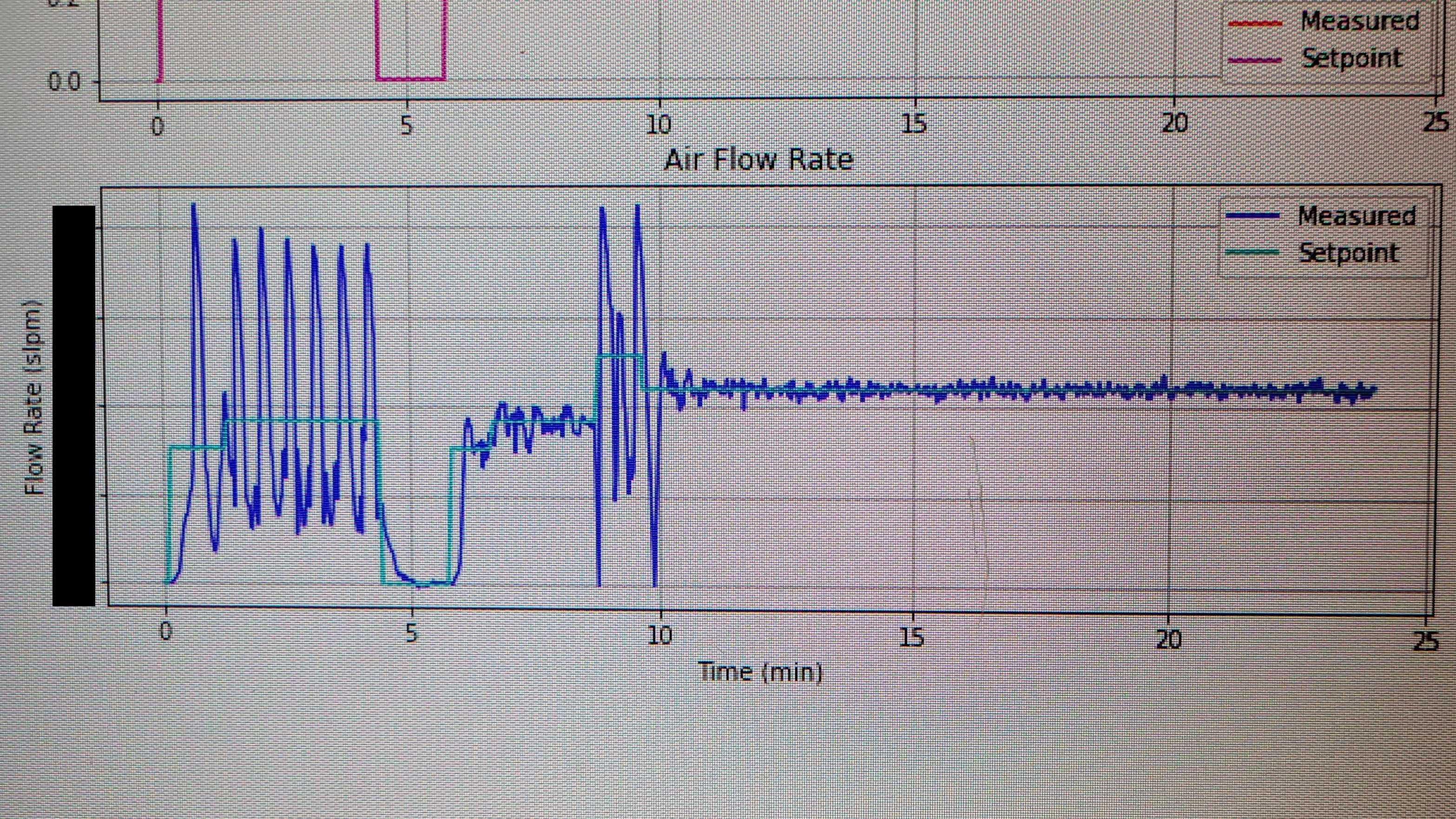

A Sensirion flow meter provided feedback for PID flow rate control.

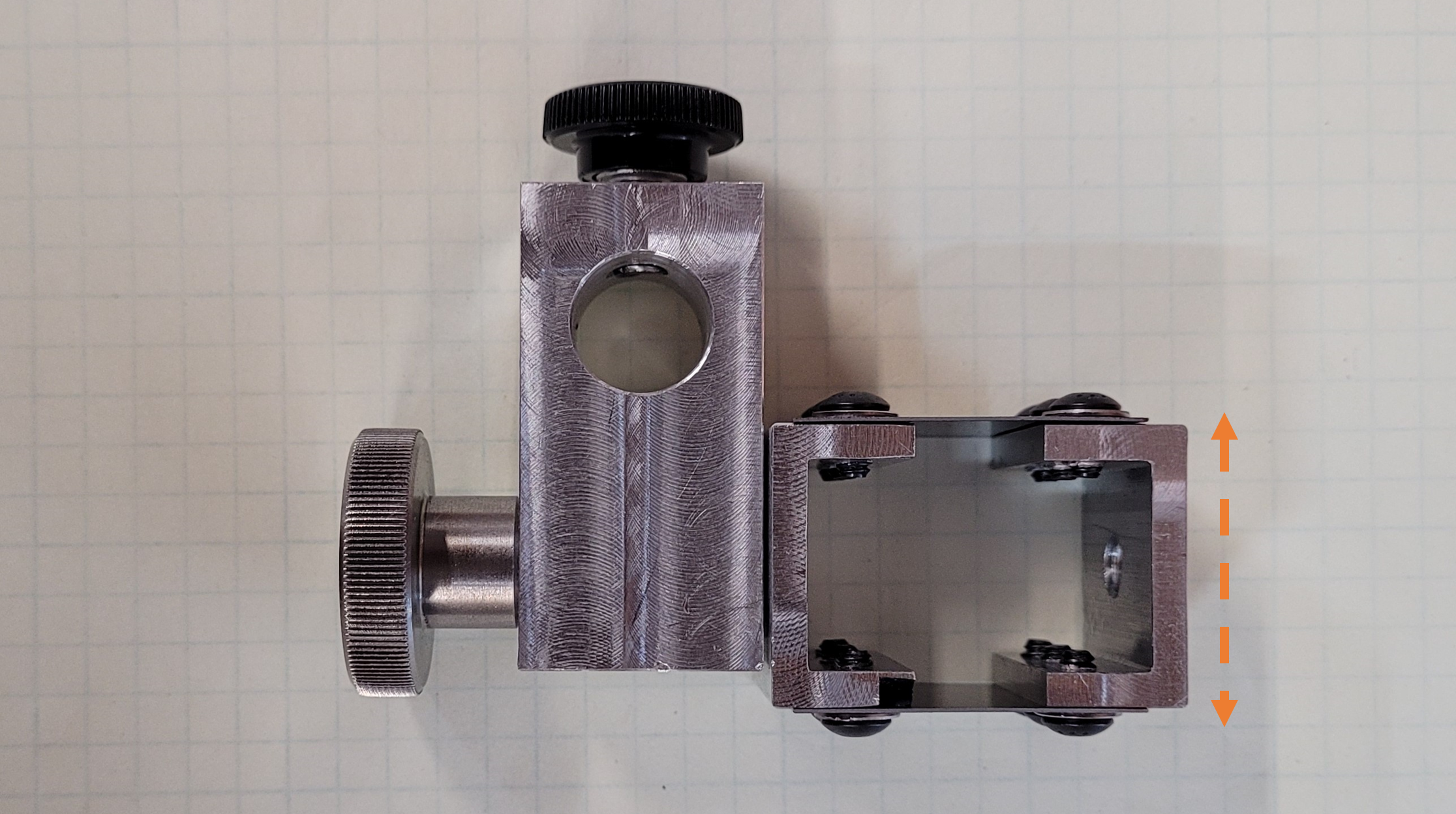

Each iteration slowly reduced overall power requirements from 48W to 7W through improved blower selection and more efficient air flow paths.

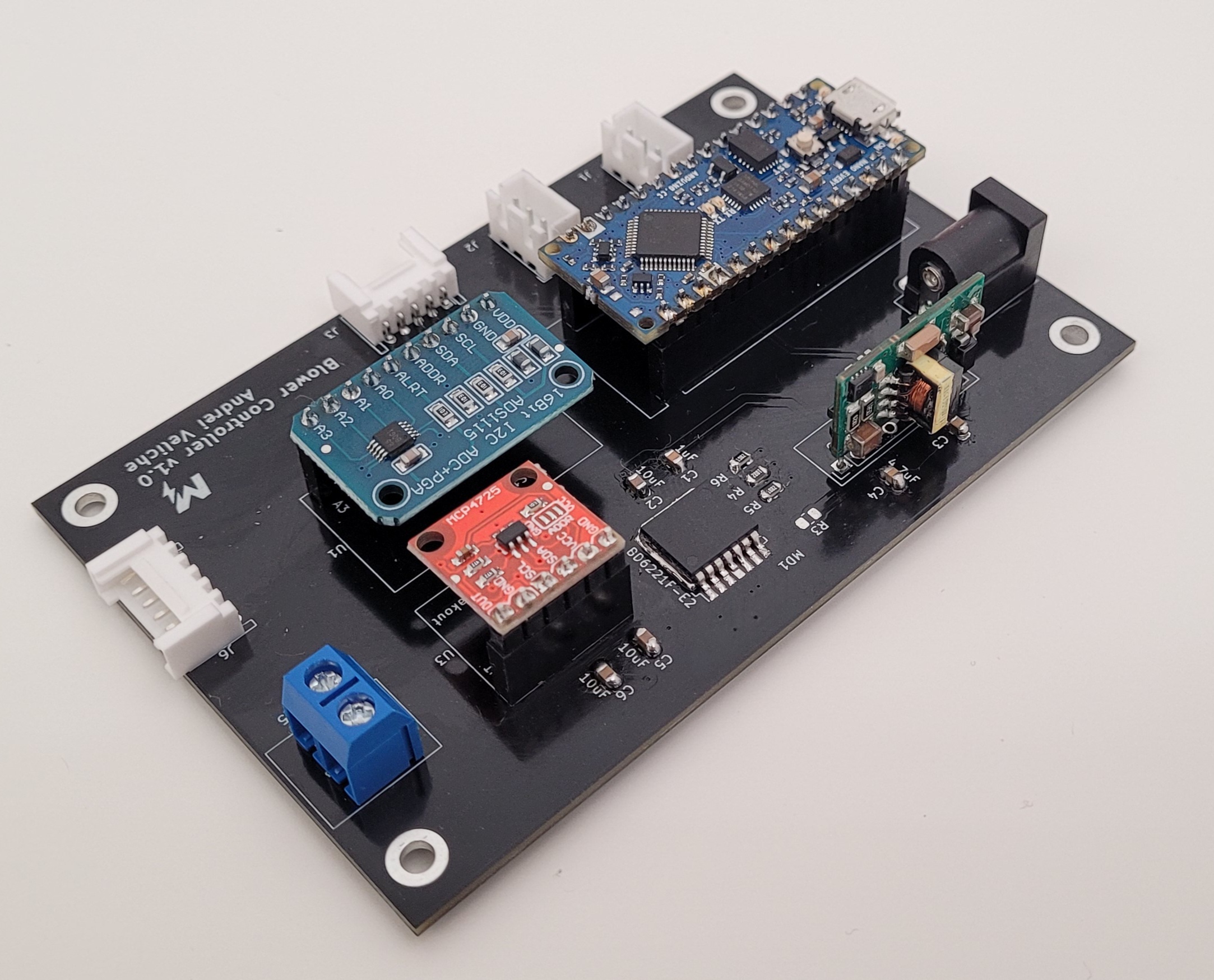

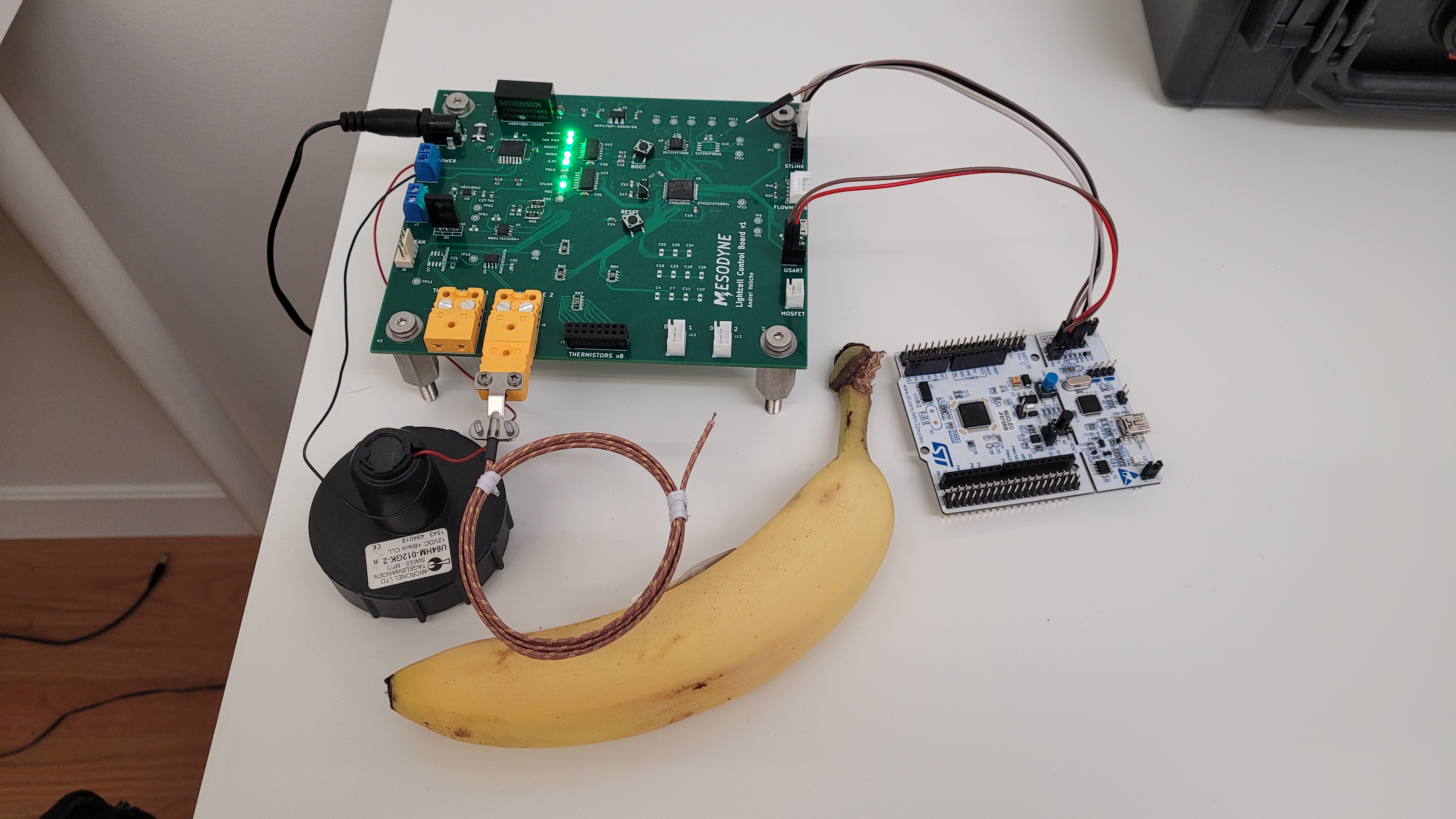

Final PCB and Testing

The final PCB was built around the STM32F07 family of MCUs due to their accessibility. Onboard are the following components.

- Thermocouple amplifiers for temperature sensing.

- Analog-to-digital converters for thermistors.

- 32MB of flash memory for data collection.

- Power MOSFETS for turning on 12V systems.

- Motor driver for the blower.

- I2C, SCL, and ST-LINK communication lines.

A major challenge was to subdue turbulent fluctuations in airflow right after ignition, casued by rapid thermal heating and acoustic resonance. A combination of PID tuning and acoustic dampening was used to achieve stability.