One-size-fits-all Smartphone Fixture

What the Customer Wanted

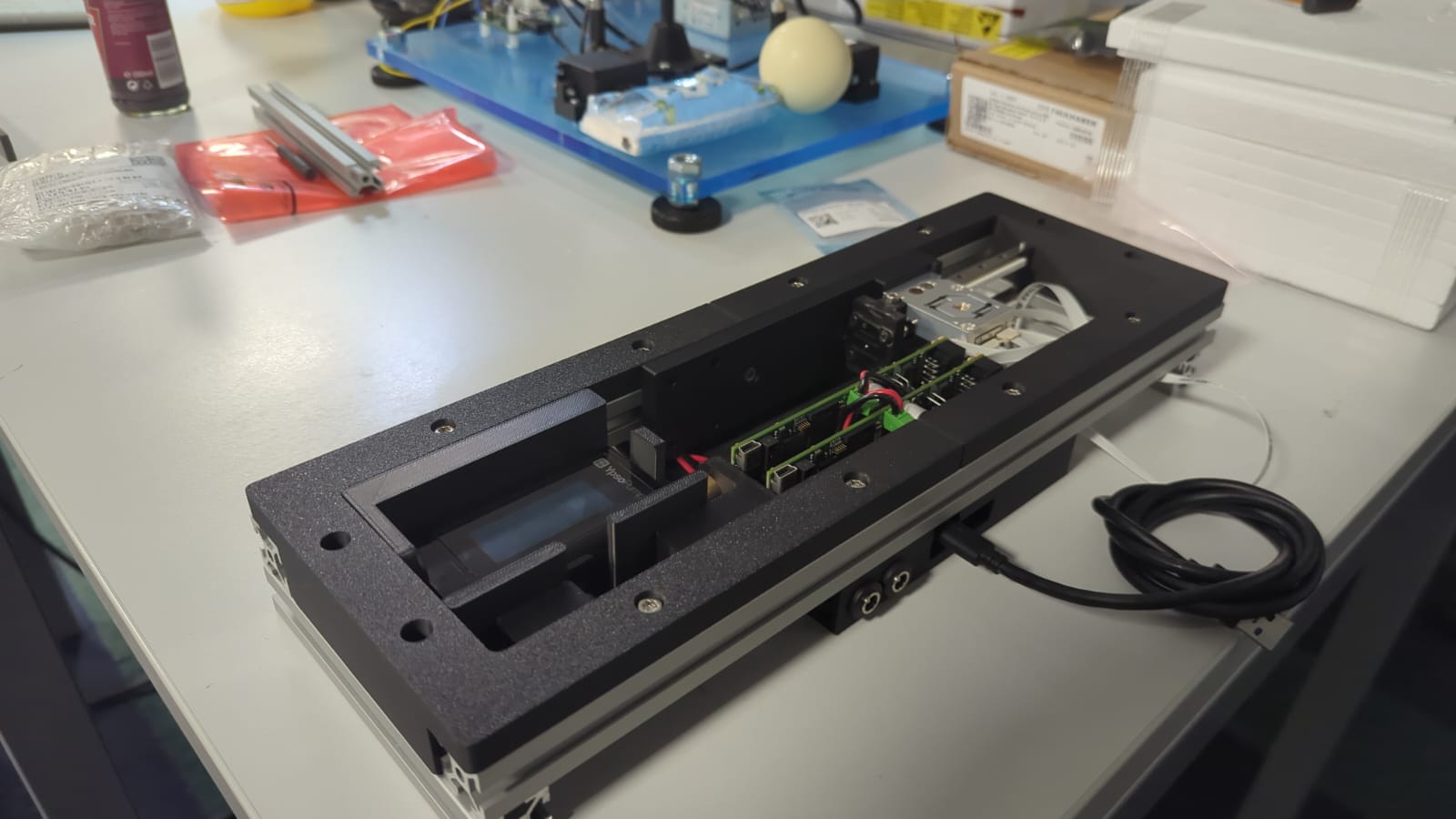

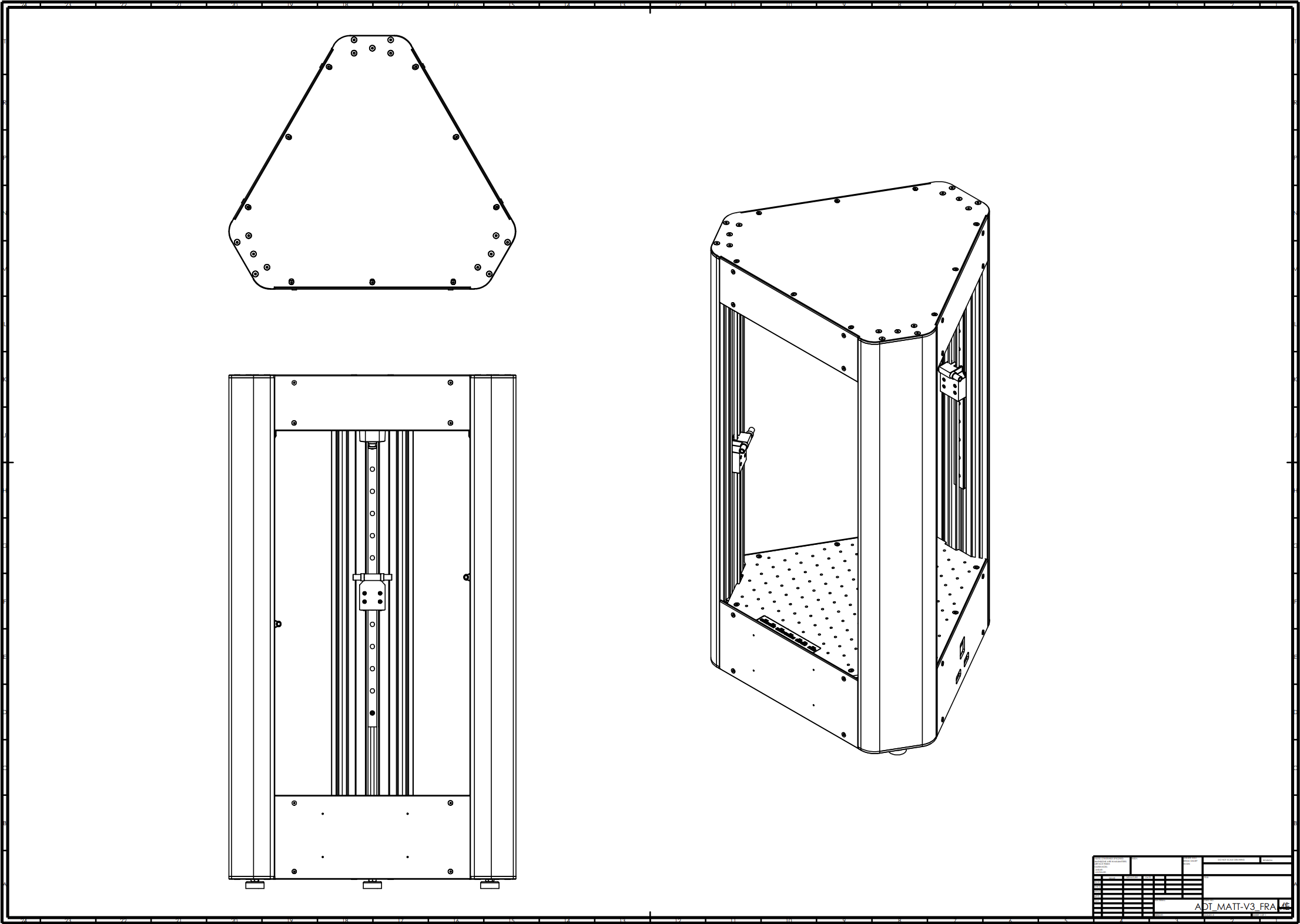

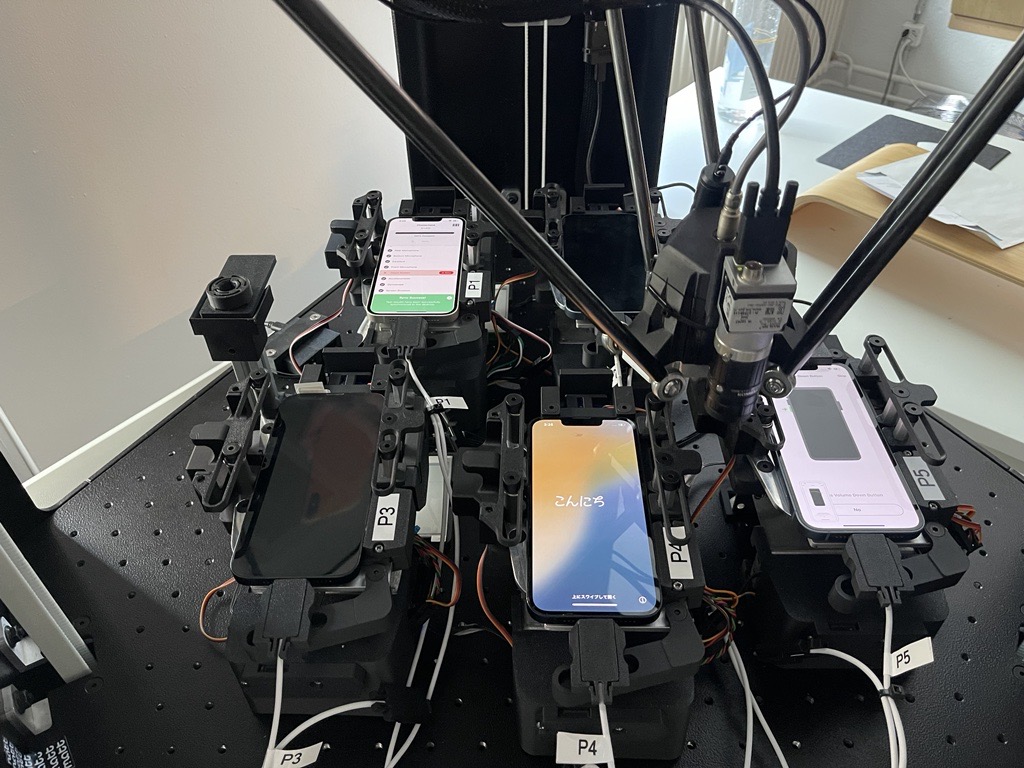

- To run functionality tests on refurbished smartphones using our MATT robot.

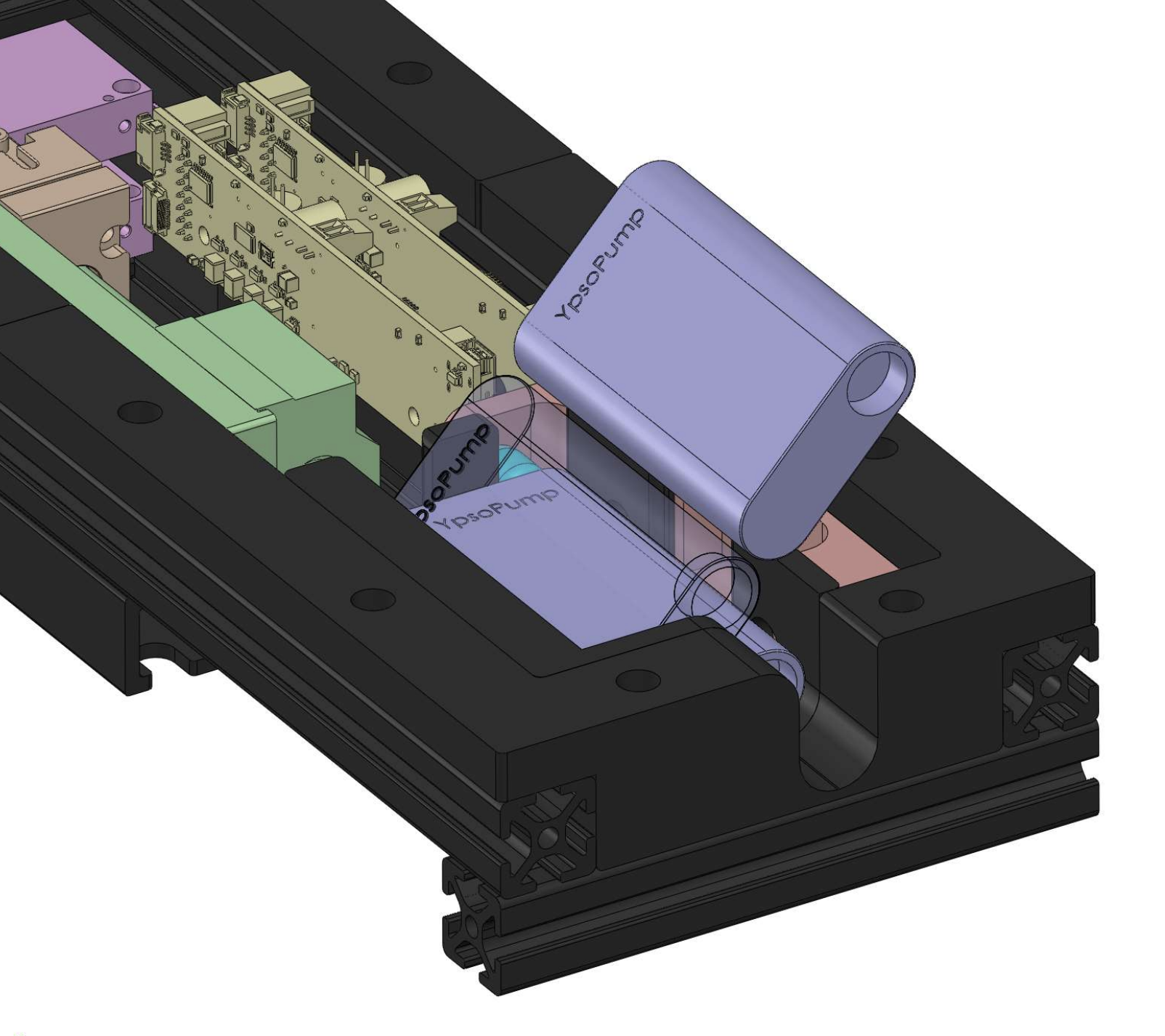

- Fit multiple fixtures on the same platform and run functionality tests in parallel.

- Functionality tests should consider the cameras, speakers, screen, side buttons and haptics.

What We Delivered

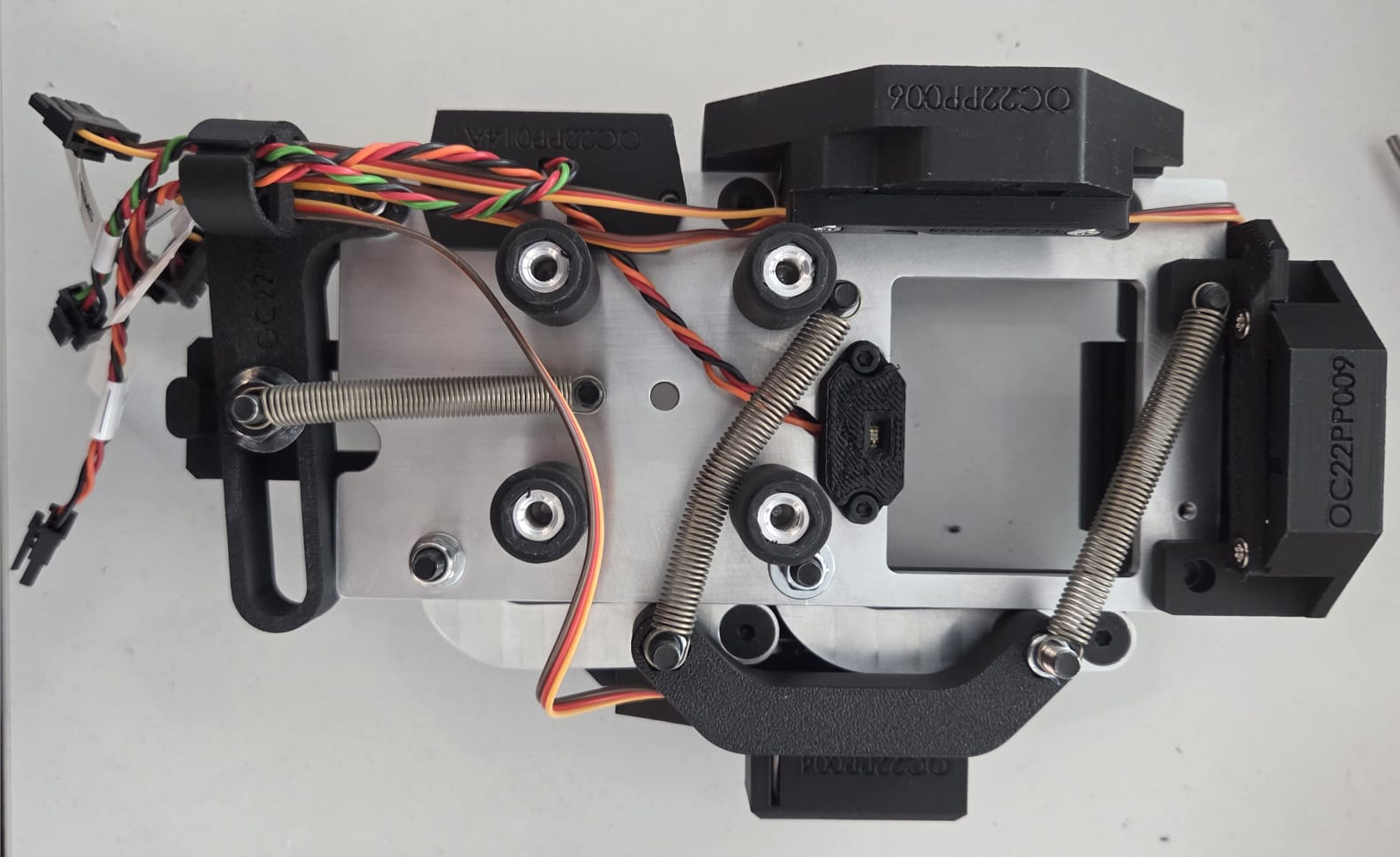

Our smart fixtures were designed to be operated single-handedly and quickly, reducing setup time to less than 7 seconds per device.

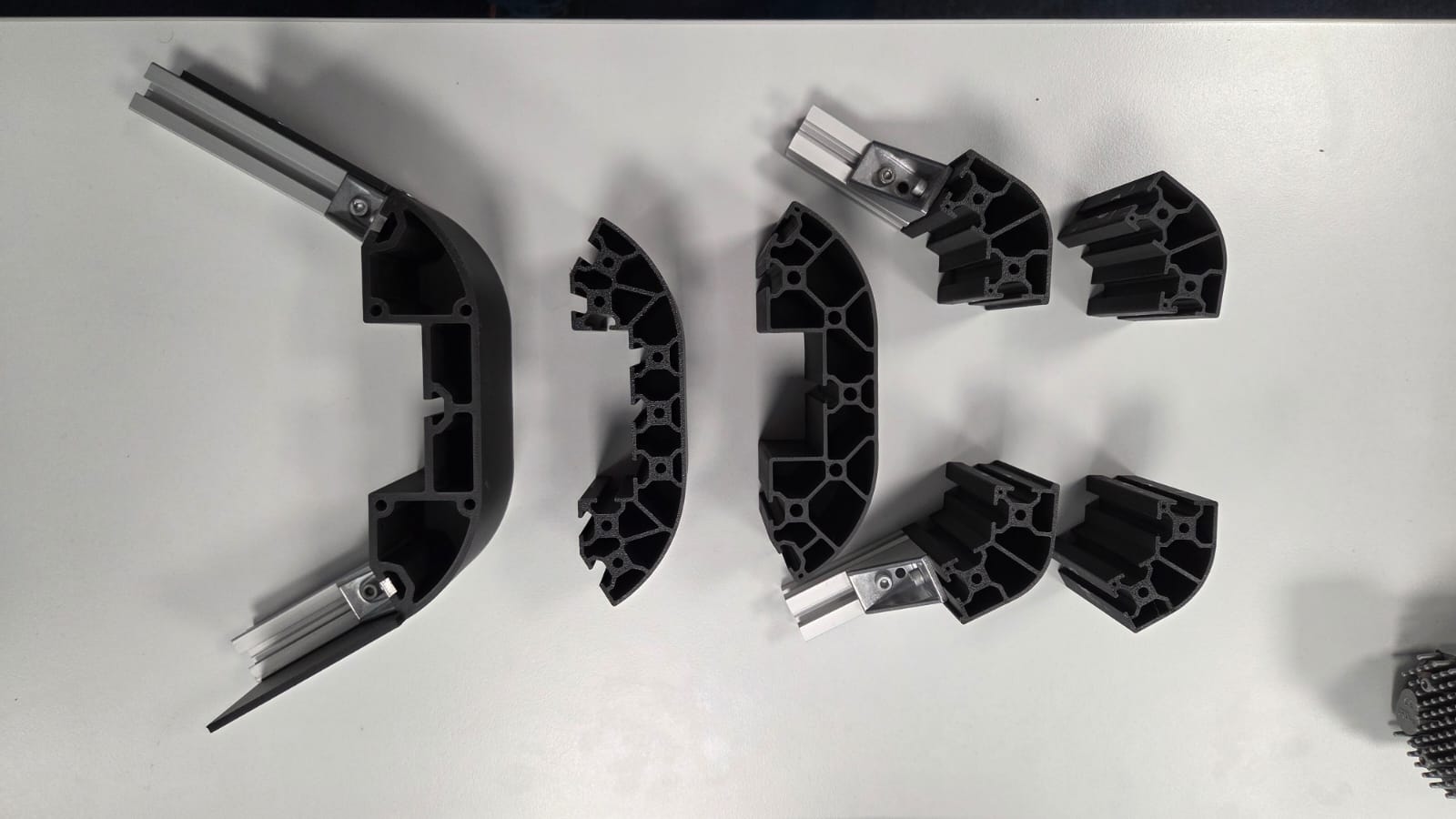

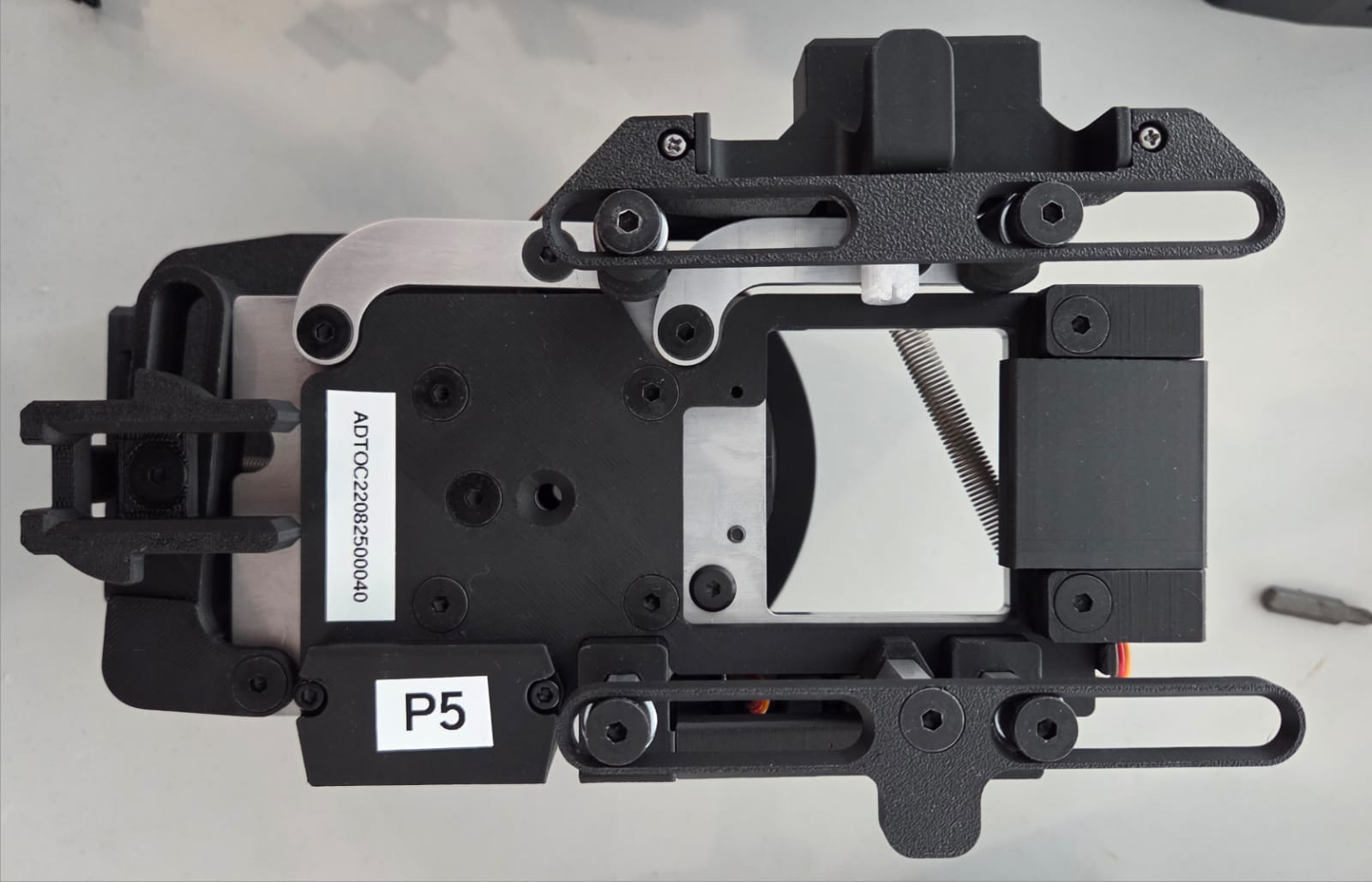

The fixtures were robust enough to withstand multiple weeks of testing yet modular enough to allow for a quick swapping of worn parts.

We aimed to primarily accomodate the iPhone lineup but extended to some newer Samsung devices too.

What worked and what didn't

Thanks to the power of FDM 3D printing, I was able to iterate through dozens of designs before converging to a dependable one.

The most challenging sub-module was responsible for actuating the mute switch on iPhones. It needed to be confined in a tight space and be dependable enough not to cause false positives during tesing. Compliant mechanisms were explored in depth but they proved to be inadequate in an industrial environment.

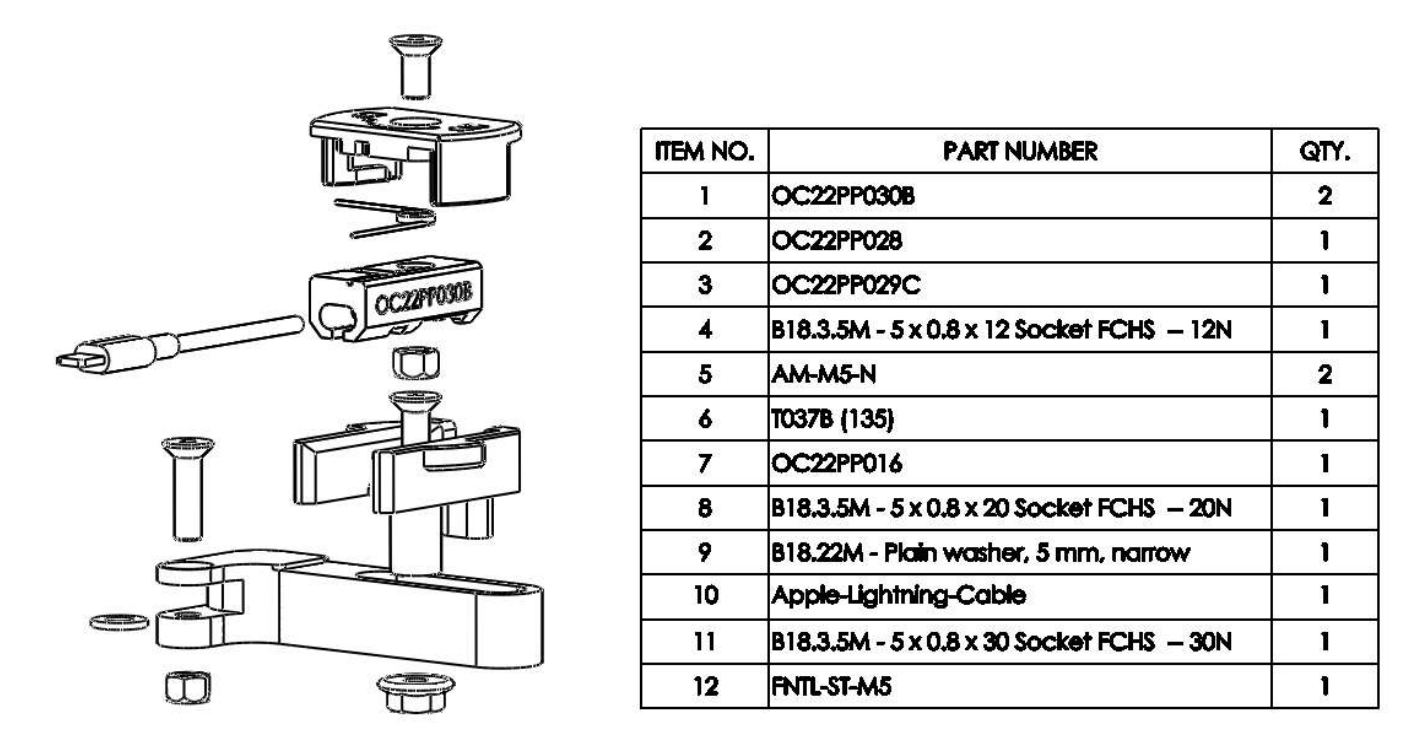

What was documentated

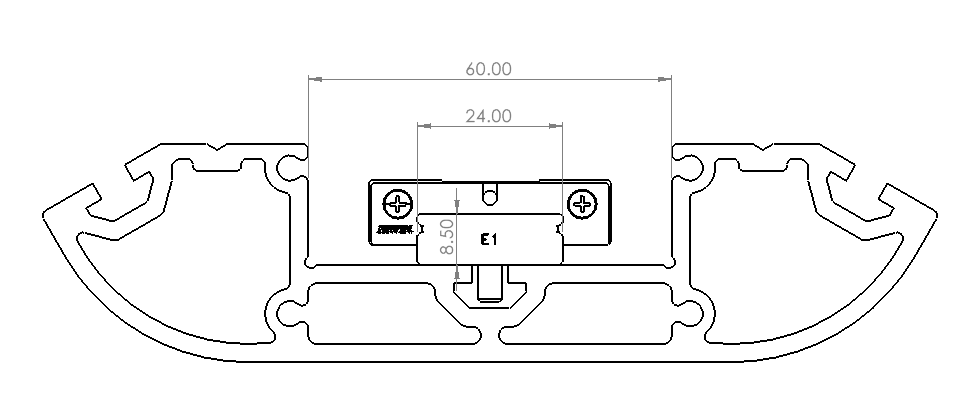

To confront the inevitability of miscommunication, I also prepared documentation on how to assemble the mechanical components and electrical wiring.

All part markings corresponded to their ID in the bill of materials. This helped reference their version information as well as material composition and variant number.